01

PROCESSES AND SERVICES

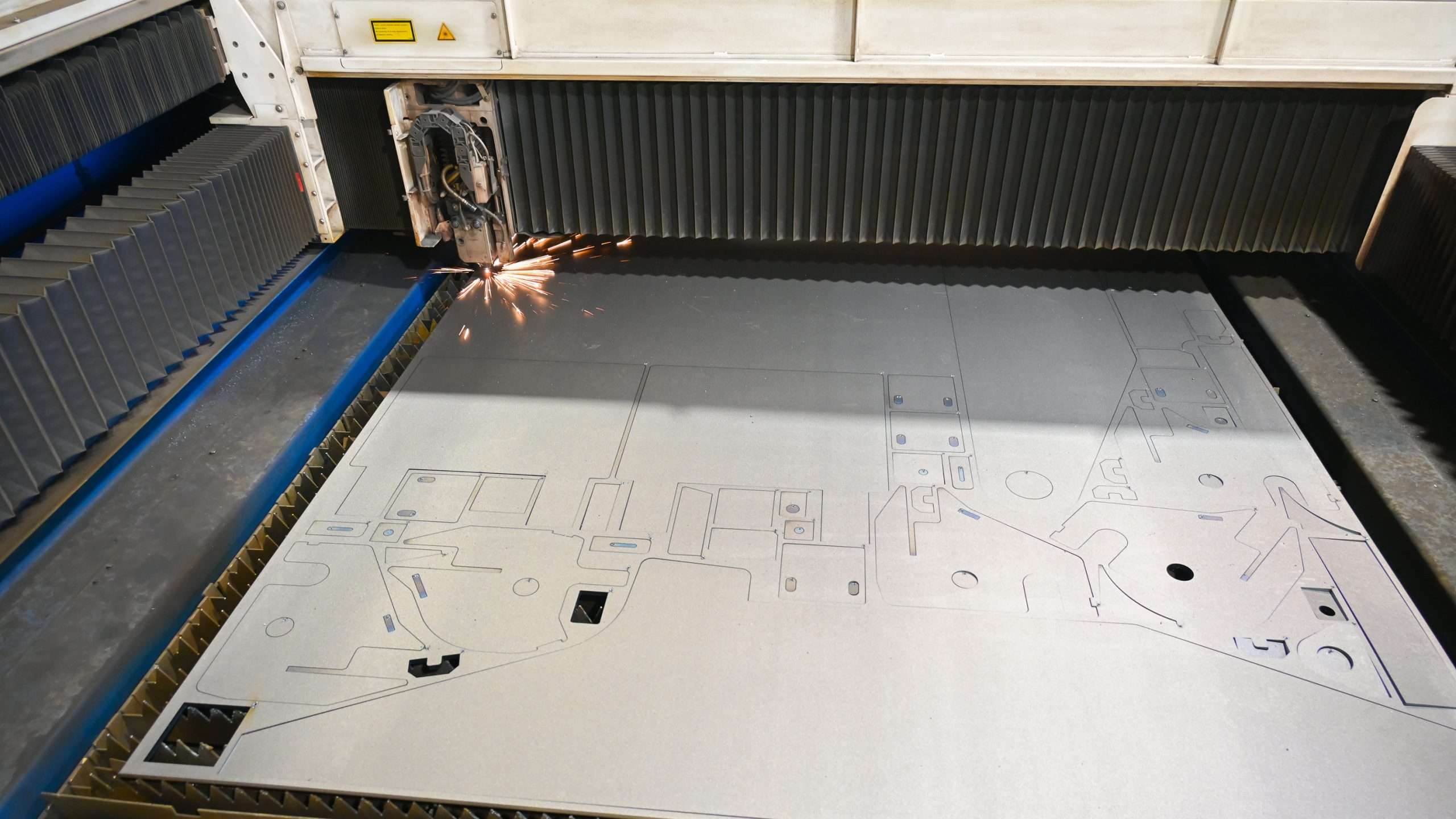

Metalna Senovo’s machine park is one of the most modern in the country, based on large-scale machining. The final products, subassemblies and layouts of very complex machines and devices are precisely machined. At our disposal we have modern CNC processing machines and top-quality clamping, cutting and measuring tools. We are aware, that even the most modern equipment does not work without highly educated personnel. The process of machining requires specific knowledge and experience, which is why young and already employed colleagues are continuously educated. We use the CREO software package from the American manufacturer PTC for design and machine programming. In addition to paper documentation, .pdf, .step, .iges or all files within CREO are welcomed.